Ed. Note: In high performance computing lore, it is said that Apple Computer bought a Cray supercomputer in the late 1980s to help design the company’s next personal computer. When he learned of this, the founder of Cray replied that ironically he was designing his next supercomputer with an Apple computer. Today, computer engineers working for the AweSim initiative are using supercomputers to design all matter of products and processes.

Ed. Note: In high performance computing lore, it is said that Apple Computer bought a Cray supercomputer in the late 1980s to help design the company’s next personal computer. When he learned of this, the founder of Cray replied that ironically he was designing his next supercomputer with an Apple computer. Today, computer engineers working for the AweSim initiative are using supercomputers to design all matter of products and processes.

If there’s one constant in the world of high performance electronic devices it’s the continued push to create smaller, lighter equipment packed with greater capabilities. After all, we all want the newest sleekest, coolest smartphone with a step up in functionality.

Those expectations are the same for all high performance electronic devices, but they do create challenges for designers. All the added features of the last decade have led to a dramatic rise in power density. That increase comes with a cost: the need to control or dissipate the associated thermal energy to maintain performance and long-term operation.

In general, a new device’s thermal behavior is one of the last things to be considered in the design cycle – following form and functionality. From the designer’s standpoint, getting traction on thermal challenges early in the design process may be difficult for a few reasons:

- Estimating heat transfer rates before prototypes are available is not easy;

- Allowable thermal margins may be masked by inherent limitations of the estimates that are made even after prototypes are made;

- Waiting for sufficient testing can be a time-consuming and expensive process.

One obvious solution to overcome these problems is to leverage virtual prototyping to perform accurate thermal assessments of devices early in the design process. However, virtual prototyping requires the use of specialized software and hardware, as well as highly skilled technical personnel. Any one of these could be a significant hindrance, but when all three are combined the resulting obstacle to using virtual prototyping may become insurmountable for all but the largest companies.

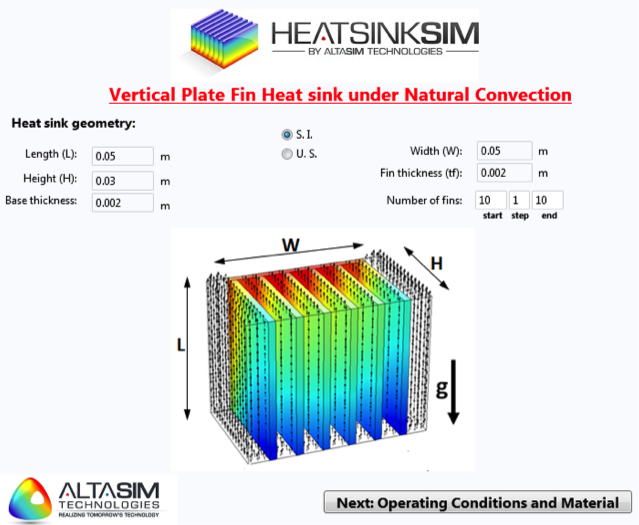

A solution we developed following discussions with many of our customers, who range from large multinational organizations to small developers, was to use apps (computational simulation applications) to explore the thermal behavior of power electronic devices in which the complexity of the calculations and access to hardware are automated for the user. The result was a HeatSinkSim app – the first of a series of apps AltaSim Technologies has developed for use through AweSim – to provide designers with the capability to examine the effect of heat sink design on thermal dissipation in power electronic components.

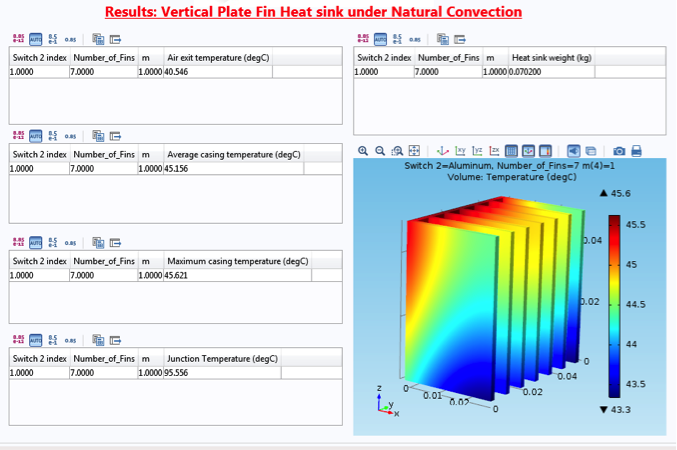

HeatSinkSim solves the heat transfer problem for a vertically-oriented plate fin heat sink operating under natural convection and offers two levels of analysis. First, the app performs a study of heat sink design parameters to identify the optimum heat transfer, and second, it conducts an optional detailed analysis that provides highly accurate temperature distributions for the optimum design of heat sink.

The user inputs the heat sink geometry, materials of construction and operating conditions. Once the desired conditions are established, the associated computational analysis file is automatically generated and submitted for execution. When the analysis is complete, the user can review the results and download a standardized report.

Heat transfer is analyzed as a combination of conduction, convection and radiation with a full solution to the associated thermal and fluid flow problem. Consequently, significant computational resources — such as those we’re currently accessing at the Ohio Supercomputer Center — are required to provide an accurate solution, and thus HeatSinkSim has been configured to run on cluster computing hardware to solve within acceptable times.

To allow widespread access to the app and the hardware required to run the simulations, AltaSim has made the app and a variety of options available to users through AweSim. The app can be accessed and run remotely through secure connectivity to ensure proprietary information remains confidential.

For more information on HeatSinkSim, contact Jeff Crompton at AltaSim Technologies (jeff@altasimtechnologies.com) or Alan Chalker at OSC (alan@osc.edu). And be sure to follow us on Twitter @AweSimApps for more updates and great information regarding high performance computing and the benefits of modeling and simulation.