In today’s tech world, everyone is either using or seriously considering computing to optimize their product designs or manufacturing processes. A number of recent blog posts have discussed the benefits of modeling and simulation. In addition, in the context of AweSim, unique modeling and simulation solutions or opportunities targeting small- to medium-sized business to operate without high infrastructure and computing costs and risk have been outlined. AweSim’s approach delivers low-risk, low-cost access to remote desktop software tools and to specialized domain applications (apps).

Competition is fierce with major OEM price point pressures for the small- to medium-sized manufacturer companies. Suppliers are struggling with slim margins while trying to maintain lean and productive operations. To keep pace with their customers – large OEMs that have access to High Performance Computing (HPC) – small- to medium-sized companies need a technological advantage. To be leading members of the supply chain, a competitive edge is necessary – this is where applying modeling, simulation and data analysis would provide this advantage.

WHERE ARE WE GOING?

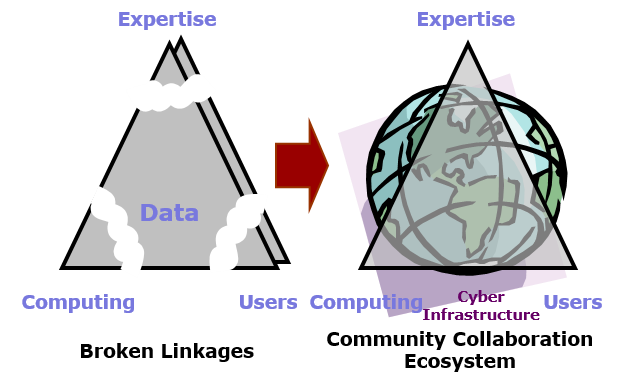

AweSim provides a significant boost or opportunity for small- to medium-sized business in this very competitive supply chain environment. However, simply gaining access to low-cost, easy-to-use software applications in a remote desk environment is not sufficient in the years ahead. Manufacturing OEMs are now looking for ways to encourage the optimization of the design of products from their suppliers and integrate supplier generated manufacturing process data in their smart manufacturing supply chain journey. As a result, the community is being driven by customer demand and desire to deliver unique design and data analytic workflow capabilities in a collective environment. This includes cultivating platforms or ecosystems that are collaboratively secure, multi-tenancy, multi-site cloud based communities of interest comprising of community inspired marketplaces of applications, libraries, APPs workflows, IP, and diverse data for a group of individuals to share task progress and production in a real-time setting. This desire will not only require new technical approaches but also new cooperative win-win business arrangements between suppliers and the OEMs.

HOW WE’RE GETTING THERE?

Early pilots of these collaborative eco-systems has allowed for production optimization, improved processes, open software, and better communication and data across the manufacturing enterprise. The collaborative sharing of common application toolkits and testbeds allows firms to mutually and simultaneously develop and validate enabling platform technologies; demonstrate reduced energy and excess, accelerate time-to-market, become more efficient and cost-competitive through collaborative digital means.

Nimbis Services has developed and piloted collaborative community under funding from the DoD and DOE for DoD microelectronics and Smart Manufacturing supply chain communities. These communities can now share for the first time in the design, development and production-to-consumer through use of applications, toolkits and testbeds with a higher degree of success.

HOW TO ENGAGE!

On June 20, 2016, President Barack Obama announced a $70M million federal award to the Smart Manufacturing Leadership Coalition (SMLC), an industry-led national non-profit, to create a nationwide Smart Manufacturing Innovation Institute. The Institute will fuel industry growth and innovation nationwide with more than $140 million in public-private investment geared toward developing advanced manufacturing technology and a supporting workforce and education pipeline.

Nimbis Services will leverage their technology in providing the basis for an open-source digital platform to integrate advanced sensors, control, platforms and modeling technologies into commercial smart manufacturing systems. This collaboration platform will also provide the manufacturing communities with easy and affordable access to real-time analytic tools, test infrastructure, and industrial applications.

The announcement was made at the Select USA Summit in Washington, D.C.

The Clean Energy Smart Manufacturing Innovation Institute (CESMII) will be an industry-led non-profit organization headquartered in Los Angeles, California with networked regional centers across California, Washington, New York, North Carolina and Texas. The national network will work across business, workforce and technical focus areas, leveraging each region’s unique industrial environments. It will be the ninth institute awarded under the National Network of Manufacturing Institutes initiative. The SMLC brings together a strong collaboration of nearly 200 partners from academia, industry and non-profits across over 30 states. The Institute will accelerate the development and adoption of advanced sensors, data analytics, and controls in manufacturing, while reducing the cost of these technologies by half and radically improving the efficiency of U.S. advanced manufacturing. The Institute will enable small, medium and large manufacturers, new and unprecedented access to smart tools, innovation and the ability to grow their business. For more information, please access the White House Fact Sheet.